The Duty of Foam Control in Enhancing Item Top Quality and Performance

Foam control is an often-overlooked yet important component in the pursuit of item high quality and operational performance throughout varied markets. This conversation will certainly explore the diverse impact of foam on both item stability and manufacturing procedures, elevating vital questions concerning the techniques that can be employed to optimize foam control.

Understanding Foam Formation

Foam development is an intricate phenomenon that can considerably impact item quality and functional effectiveness across numerous sectors. It occurs when gas bubbles become entraped in a liquid, bring about the production of a frothy framework. A number of elements contribute to this procedure, consisting of the chemical and physical buildings of the fluid, the visibility of surfactants, and the conditions under which blending occurs. Recognizing these variables is vital for managing foam successfully.

The liquid's viscosity and surface area tension play essential roles in foam security. Surfactants, as an example, can decrease surface area stress, advertising bubble formation but also enhancing foam security, which can be bothersome in certain applications. Mechanical anxiety, temperature level variations, and the presence of impurities can exacerbate foam generation, making it essential to keep track of these elements throughout manufacturing processes.

Industries such as food and drink, drugs, and chemical production should be especially alert concerning foam control. By comprehending the hidden systems of foam development, organizations can apply targeted strategies to reduce its effects, thus maintaining operational effectiveness and ensuring consistent product efficiency.

Effect On Item High Quality

The existence of foam can substantially jeopardize item high quality across various industries. In manufacturing procedures such as food and drink, drugs, and cosmetics, extreme foam can result in inconsistent item formulations. In food manufacturing, foam might trap air, affecting appearance and taste, which can eventually alter customer understanding and complete satisfaction.

Moreover, foam can prevent the uniformity of coverings and paints, causing flaws like bubbles and uneven coatings. In pharmaceutical applications, foam can disrupt the accurate application of liquid medicines, potentially impacting therapeutic efficacy and client safety and security. These high quality issues not only lessen completion item's appeal however can additionally cause expensive recalls and damage to brand reputation.

In addition, the existence of foam can complicate quality assurance measures, making it difficult to attain specific measurements and consistent results. Reliable foam control not only alleviates these risks however additionally enhances general item top quality by guaranteeing that solutions meet strict sector standards. By buying foam control approaches, companies can protect their items, boost customer fulfillment, and keep a competitive edge in the market.

Functional Challenges From Foam

Effective operations in numerous sectors can be significantly interfered with by the visibility of foam, which poses multiple difficulties throughout manufacturing procedures. Foam can prevent blending and response times, impeding the efficiency of chemical processes. In industries such as food and beverage, foam formation can result in unreliable fill degrees, causing item waste and incongruities in product packaging.

In environments where hygiene is critical, such as pharmaceuticals and food processing, foam can make click reference complex cleaning methods, creating hidden reservoirs for contaminants. This not only increases quality concerns but also can result in compliance issues with regulatory standards.

Furthermore, the psychological influence on operators can not be overlooked; too much foam can develop a disorderly workplace, resulting in reduced morale and productivity. In recap, resolving the functional difficulties positioned by foam is vital to maintaining efficiency and item top quality in different industries.

Strategies for Reliable Foam Control

Exactly how can industries efficiently reduce the challenges presented by foam? Effective foam control approaches are necessary for improving item high quality and functional effectiveness. One primary technique is the use of defoamers, which are chemical representatives developed to lower or get rid of foam development. Selecting the ideal defoamer calls for an look at here extensive understanding of the details process problems and the materials included.

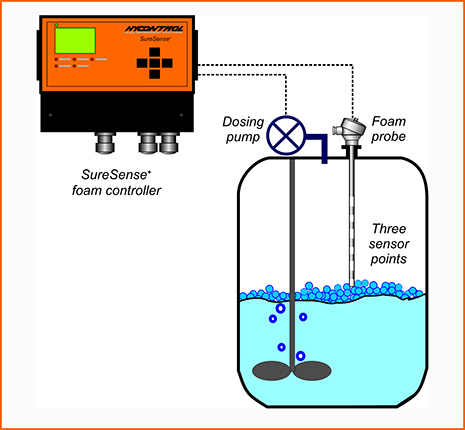

In addition to chemical options, process optimization plays an essential function in foam monitoring. Industries can assess and change criteria such as blending temperature, speed, and stress to reduce foam generation. Carrying out tools alterations, like setting up foam-breaking devices or adjusting container design, can even more aid lower foam levels.

Normal monitoring and moved here analysis of foam behavior within production processes are also important. Using sophisticated sensors and analytics can supply real-time information, enabling prompt treatments and modifications. Personnel training is similarly crucial; making sure that employees are educated concerning foam characteristics and control methods can cause positive foam administration.

Study and Industry Applications

While many industries encounter one-of-a-kind difficulties associated with foam control, case studies disclose that customized techniques can considerably enhance both item high quality and operational performance. In the pharmaceutical market, for example, a leading manufacturer implemented a personalized foam control technique that minimized foam formation during fermentation procedures. This advancement not only improved return by 15% but also decreased contamination dangers, ensuring greater product integrity.

Likewise, in the food and drink industry, a significant dairy manufacturer faced excessive foam throughout pasteurization - Foam Control. By presenting a specialized antifoam agent, they reduced handling time by 20%, which directly converted to increased throughput and lowered energy intake. The application of foam control determines ensured regular product texture and preference, reinforcing brand name loyalty

In the chemical production industry, a situation research highlighted the successful application of foam control in wastewater therapy processes. The execution of a real-time surveillance system enabled drivers to adjust antifoam dose dynamically, leading to a 30% reduction in chemical usage and enhanced effluent quality.

These situation researches illustrate the varied applications of foam control across sectors, emphasizing its important role in improving product top quality and operational effectiveness.

Conclusion

In final thought, effective foam control is essential to enhancing item top quality and functional effectiveness across various industries. Ultimately, focusing on foam control adds to enhanced efficiency, safeguarding brand online reputation, and raising consumer fulfillment, highlighting its importance in quality guarantee within making processes.

Foam control is an often-overlooked yet vital part in the search of product quality and functional effectiveness across varied markets. Staff training is just as crucial; guaranteeing that personnel are educated regarding foam characteristics and control methods can lead to proactive foam monitoring.

While numerous industries deal with special challenges connected to foam control, situation researches expose that tailored techniques can considerably boost both product top quality and operational performance (Foam Control). In the pharmaceutical industry, for circumstances, a leading producer applied a customized foam control approach that decreased foam development during fermentation processes.In verdict, efficient foam control is indispensable to enhancing item top quality and operational effectiveness throughout various markets